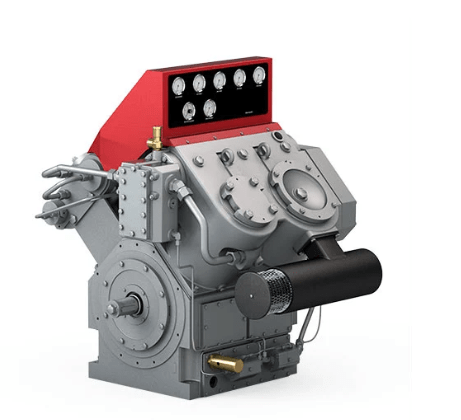

- GD products of this design used by many marine and defense naval frigates and submarines all across the world

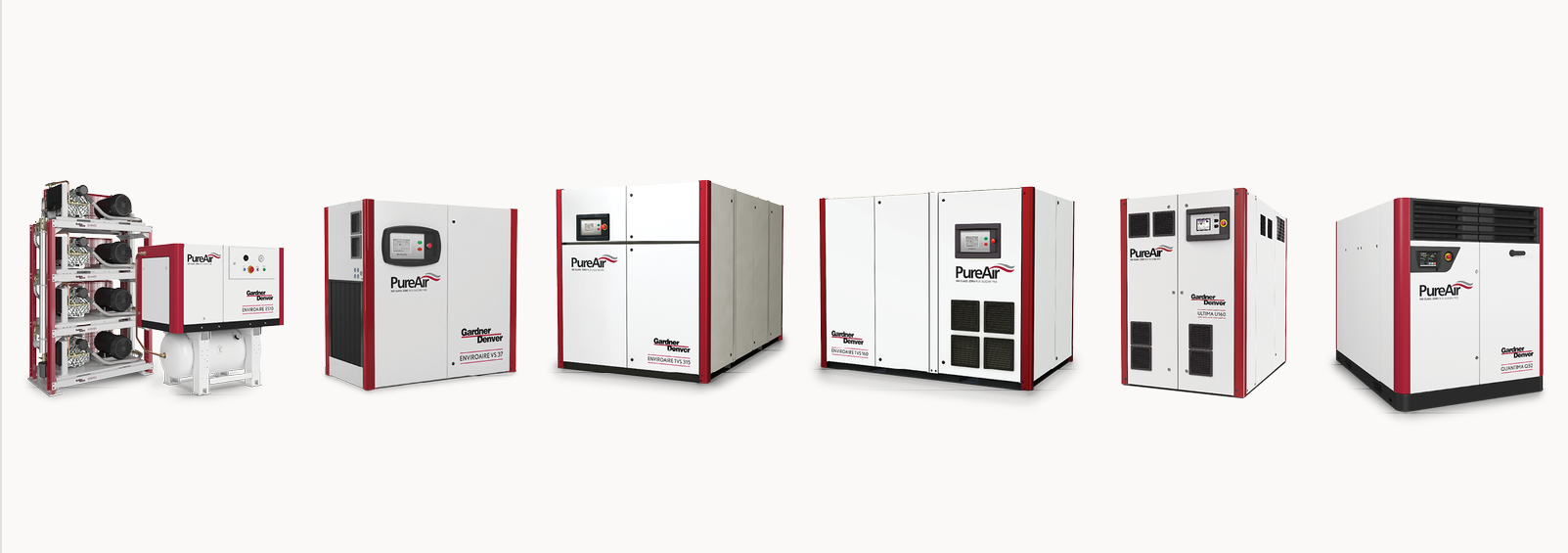

- Reputation and product portfolio based on reliability and fast service support

- 250-600 psi applications in air and water-cooled offerings

- Service support for parts or technicians via GTA Compressor Solutions Inc. across Canada

- Applications for air start, military, laser cutting etc are common.

- Reference points from long-standing users all across the world

- Customization allows for mounting gauges and moving inlet/outlet ports to match site requirements.

Reavell mid and high-pressure compressor range

Our major clients